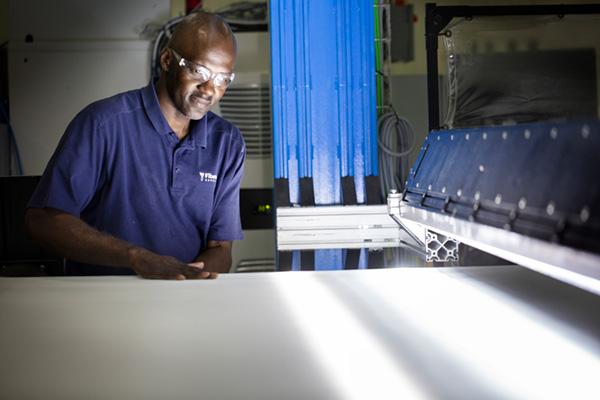

Slitter Operator

1. PURPOSE OF THE JOB

The purpose of a Slitter Operator is to set up, operate, and maintain a slitting machine to slit and rewind webs of fabric into narrower rolls. The Slitter Operator is responsible for ensuring that the machine is running efficiently and that the output meets quality and production standards. The Slitter Operator is also responsible for monitoring the machine's functions and making any necessary adjustments as needed. Additionally, Slitter Operators may be responsible for conducting regular maintenance and troubleshooting any issues that may arise.

2. RESPONSIBILITIES AND AUTHORITIES

A Slitter Operator operates slitting machines to cut and slit parent rolls of material into smaller slit doffs. They perform quality checks, inspect and remove quality defects, and adjust machine settings for size and material specifications. They also maintain and repair machines as needed. Operate slitting machines to cut and rewind parent rolls of nonwovens into narrower slit doffs.

Slitter Operator Duties

- Set up machines and make necessary adjustments to ensure quality production

- Monitor machines and make necessary adjustments to maintain quality standards

- Troubleshoot and repair malfunctions when needed

- Maintain production records

Slitter Operator Skills

- Ability to read and understand slitting instructions

- Set the machine up based on the standard operating conditions and make changes to the settings based on quality outputs

- Ability to perform basic math calculations

- Demonstrate safe work practices

Slitter Operator Personal Traits

- Attention to detail

- Good communication skills

- Ability to work with precision

- Good hand-eye coordination

- Ability to stand for long periods

- Teamwork skills

- Ability to be flexible

- To multitask effectively

- Comfortable leading others

Slitter Operator Job Summary

The Slitter Operator is responsible for operating and monitoring slitting equipment in a manufacturing environment. The Operator will be responsible for loading and unloading materials, setting up and adjusting machines, and performing quality inspections on the finished product. The Operator must have an eye for detail and an ability to troubleshoot and resolve issues in order to ensure that the finished product meets quality standards. The Operator must also adhere to all safety regulations and guidelines to ensure a safe and efficient work environment.

3. QUALIFICATIONS AND COMPETENCIES

Formal Education

- High School or GED Equivalent Required

- Associates Technical Degree a plus

Required competencies of the position

- Ability to read and understand written instructions

- Ability to set up, operate, and troubleshoot slitting machines

- Ability to use basic math and measurement tools

- Ability to lift up to 50 lbs

- Ability to stand for long periods of time

- Vocational technical training (mechanical or other)

- Ability to read an excel document

Experience

- 2-3 years manufacturing environment

- Textile Manufacturing a plus

Main Accountabilities

This position reports to the Shift Team Leader with dotted line to Production Manager.