Fibertex strives for sustainability in filter media

At Fibertex, we are dedicated to drive the sustainability agenda within our industry. It is deeply embedded in our DNA and a fundamental part of developing the business. We have a global setup close to our customers, with state-of-the art technologies and modern production facilities making superior high-performance materials and consistently reducing our carbon footprint.

Fibertex understands global market requirements for more sustainable filtration products. The Fibertex team works closely with prominent research institutes and leading manufacturers, to ensure engineered fabrics, based on state-of-the-art nonwoven technologies, are at the cutting edge of innovation in filtration solutions.

Fibertex manufactures sustainable filtration materials that enable our customers to create high-performance, energy efficient solutions, designed to improve the quality of life.

Fibertex Filter Media faces Sustainability

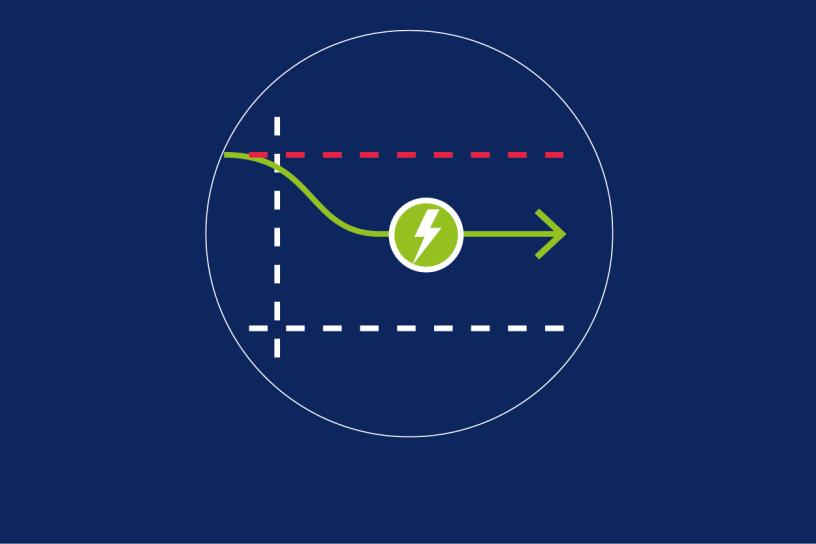

Energy-saving filtration solutions

Sustainable and biodegradable filtration solutions

Fibertex products comply with - PFAS legislation

Fibertex synthetic filter media has advantages over glass fibre materials

ECOVADIS CSR RATING

EcoVadis CSR Rating

Committed EcoVadis Sustainability Rating

2025