Groundbreaking products from Fibertex

Train speeds and traffic are increasing along with travelers’ demands and environmental concerns. Therefore, modern railway companies must work smarter – which they can do together with Fibertex.

Run more smoothly

Avoid unplanned track work leading to train delays, customer complaints, and escalating unforeseen costs by designing future-proof railways that ensure the optimum operational reliability.

At Fibertex Nonwovens, we offer you wellproven and future-proof products for the design, construction, and maintenance of railway systems. All our products will improve the reliability and performance of your railway, thanks to their ability to increase the bearing capacity – something which is extremely important when operating heavy-duty trains.

Apply F-40 Detection and stay ahead of your challenges

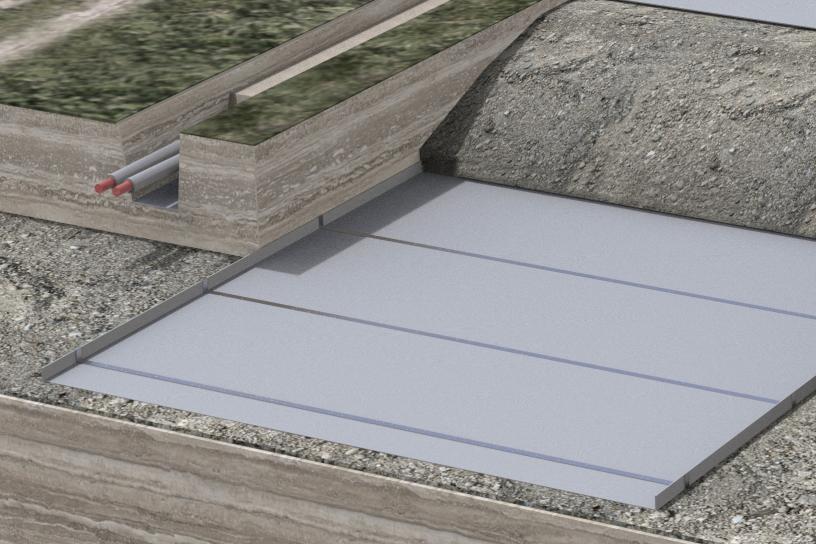

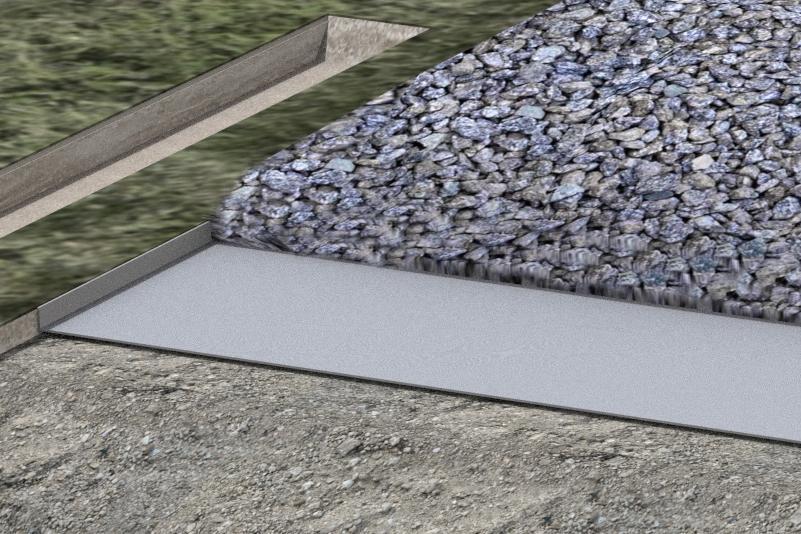

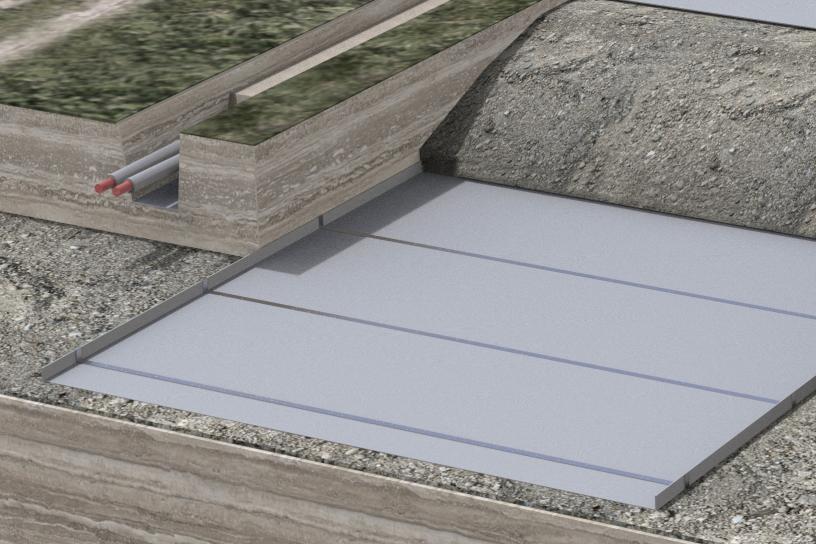

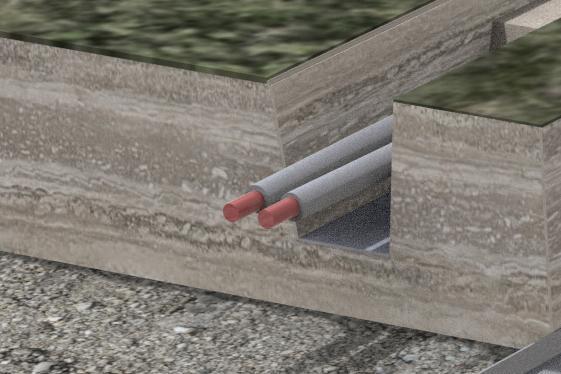

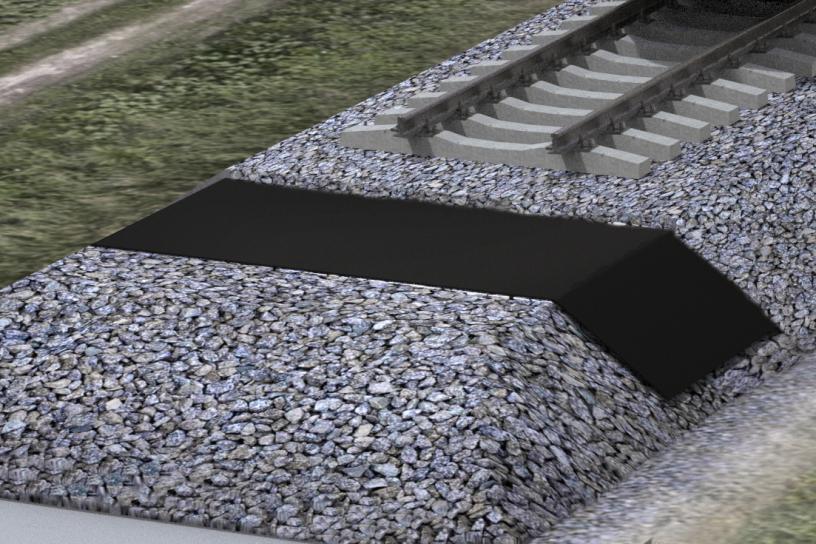

The F-40 Detection is a separation geotextile, which is placed between the subsoil and the bearing layer when installing new rails. It enables the monitoring of subsoil settlements to predict and plan maintenance.

This valuable monitoring is made possible via aluminum strips in the geotextile every five meters. The strips are detectable using georadar systems, which provide your railway managers with insights into potential strip displacements caused by subsoil movement.

These insights help you to:

- Predict future problem zones

- Improve maintenance

- Avoid erosion damage

- Improve railway safety

- Reduce renovation costs

Nothing can shock you when FiberRails ST is used

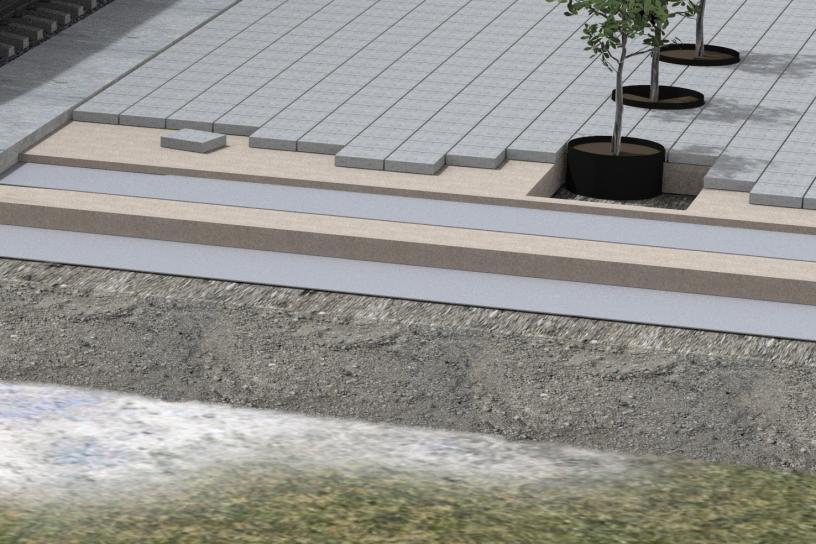

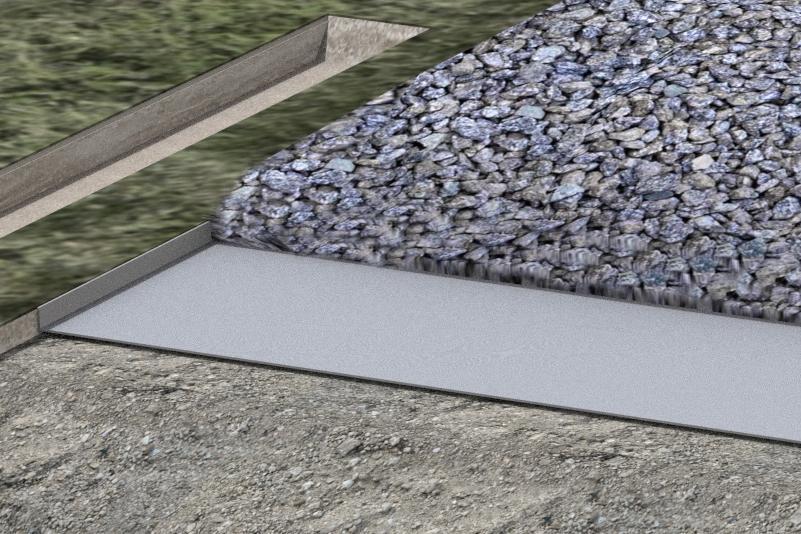

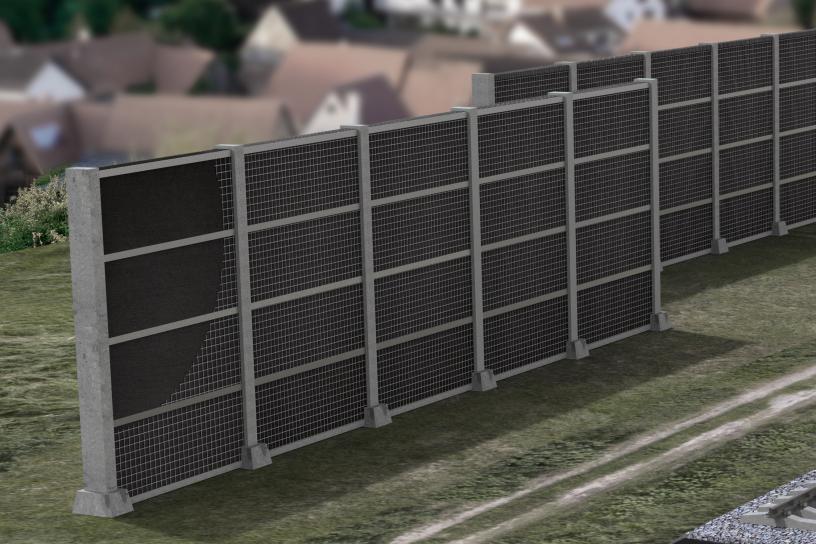

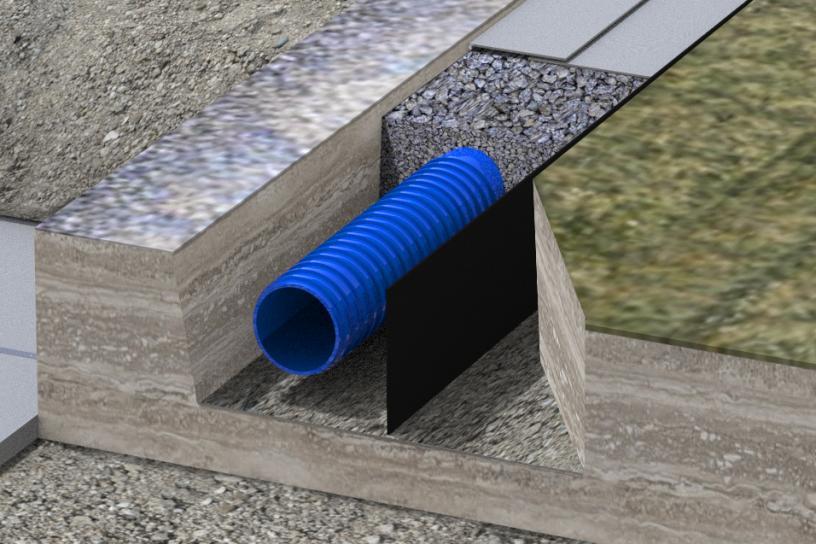

Railways are supported by ballast to ensure maximum friction. Unfortunately, over time this friction will be seriously reduced by the vibration caused by recurring traffic.

You can overcome this challenge by applying FiberRails ST to the bearing surface before laying the new ballast as it provides effective separation and filtration resulting in improved bearing capacity and service lifetime of the track. Additionally, dampening vibration also reduces noise levels, which is important, especially in urban areas.

With FiberRails ST, you will be able to improve service life and stop the critical pumping effect, helping you to:

- Ensure a reliable timetable

- Improve railway maintenance and lifetime

- Reduce noise levels due to dampened vibration

The abrasion resistance of FiberRails ST is required and certified especially for this application by the French train operator SNCF.

Find a product for your exact needs

Brochures

Contact

Find Contact Person

Find your local contact person for questions regarding specific applications by choosing your region or country.